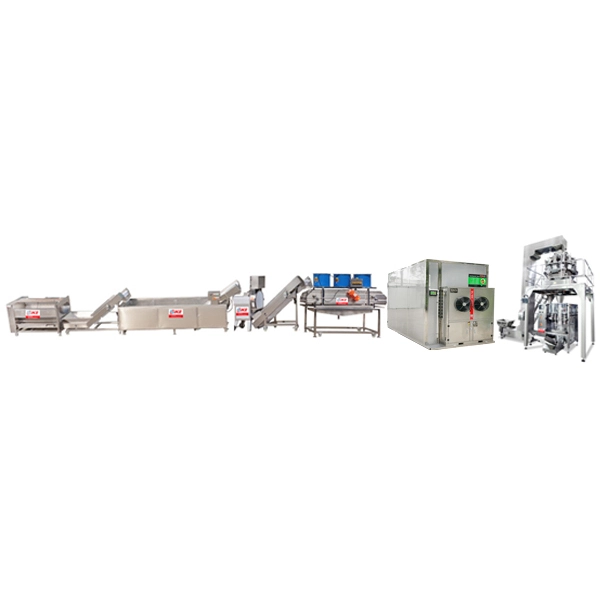

IKE Ginger Peeling, Washing, Cutting, Drying, Powdering and Packing Processing Line

Ginger processing line functions: peeling ginger, washing ginger, slicing ginger, shredding ginger, dewatering, drying ginger, powdering ginger, crushing ginger, packing ginger.

Our Advantages:

Ginger is very popular in the food market. It can be processed into snacks, seasonings, or medicinal materials. The processing steps of ginger include cleaning, peeling, slicing, drying, packaging, etc. Different needs require food machinery with different functions for processing, IKE factory In order to meet customer needs, we have developed and produced a fully functional ginger processing line, which is made up of ginger peeling machine, washing machine, cutting machine, dryer, packaging machine and other mechanical couplings. The IKE ginger production line is reasonably designed and can be greatly improved. The degree of automation in factory production improves production efficiency and reduces labor costs. The IKE production line is equipped with energy-saving technologies such as heat pumps, which can reduce energy consumption, reduce food processing costs, and increase sales profit margins. It is the best choice for the ginger processing industry, if needed For ginger processing test, please contact us to provide your requirements.

Using Area:

IKE Ginger Peeling, Washing, Cutting, Drying, Powdering and Packing Processing Line is suitable for food factories, large farms, hotel kitchens, restaurants and other places that require a lot of work. Appropriate food processing production lines can improve production efficiency, reduce labor costs, and improve product quality.

IKE offers customized food processing machines to match your needs. Tell us what you're looking for—we’ll help you find the right solution.

What else do you buy with this equipment